Purchasing a Bandsaw machine can vary from a relatively small investment to a large scale project. Sawcraft would like to suggest a series of factors that should be considered when purchasing a saw regardless of the size of the investment.

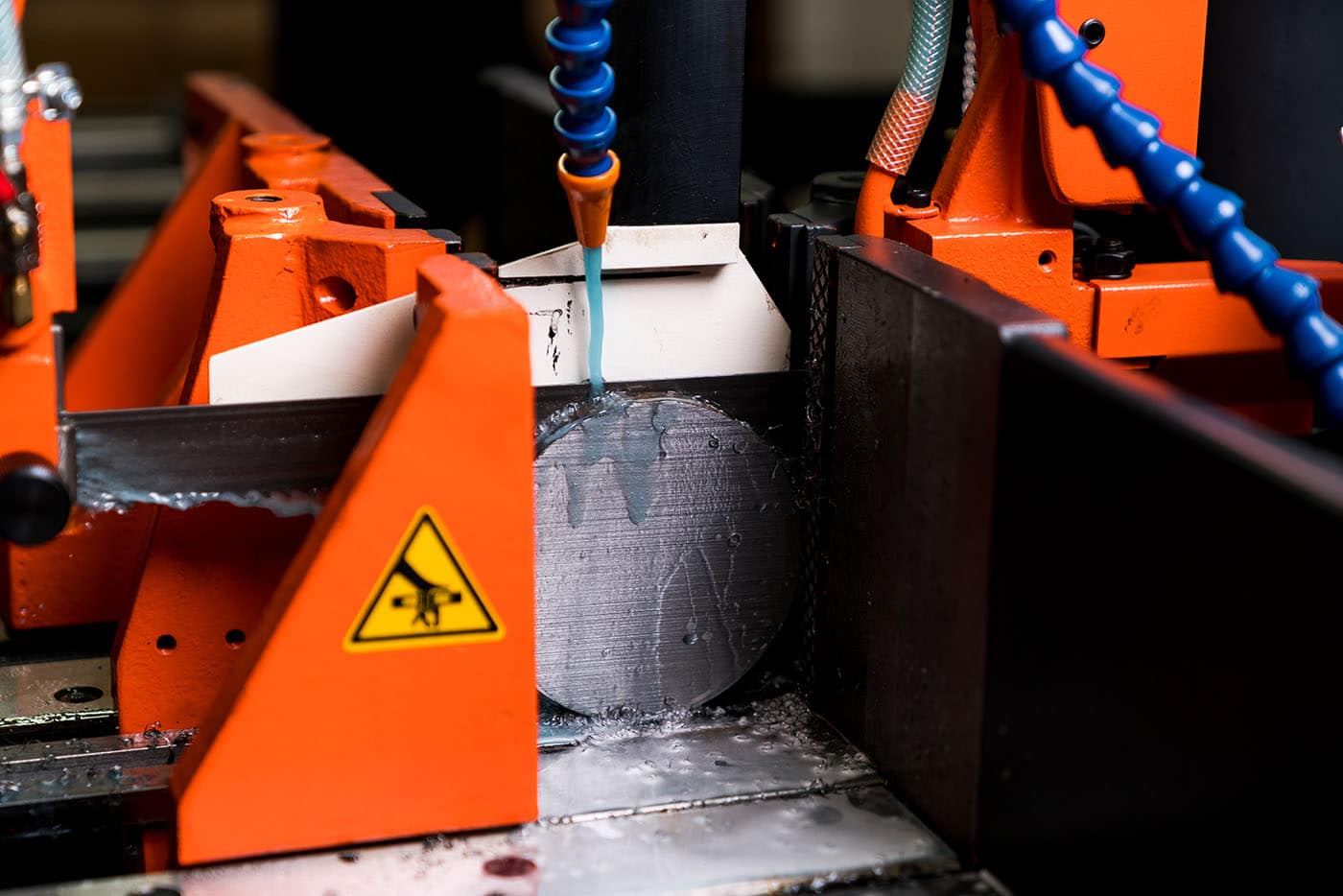

One of the first things to consider is the level of production required. Bandsaws vary from simple manually controlled saws to fully automatic CNC controlled machines. As the levels of production increase the power and automation of the saw become critical.