About T.C.T Circular Saw Blades

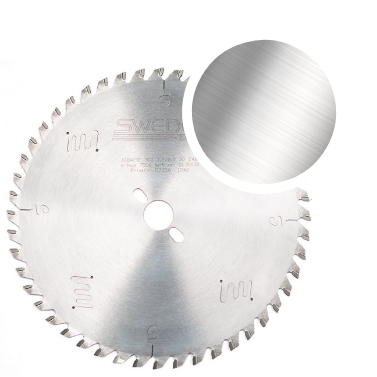

Sawcraft UK offer a comprehensive range of Tungsten Carbide Tipped, T.C.T circular saw blades for the wood, plastic and the soft metal cutting industry.

Sawcraft offers an extensive range of Tungsten Carbide Tipped circular saw blades. The range covers all types of wood working applications, aluminium, plastics and metal cutting. We stock a variety of diameters and bore sizes to cater for all types of industries and professions including the DIY.

Knowing your blade

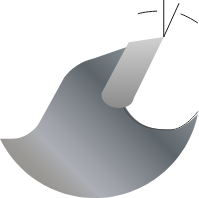

Front angle

The front angle is the number of degrees of the tooth in relations to the centre line of the saw blade

22 - 30° - Ripping of dry and green wood

5 - 15° - Crosscutting of wood, sizing of fibreboard, plasterboard, chipboard, veneered board and plywood

6 - 10° - Cutting hard plastics, veneered and laminated boards, mitre-cutting of wood and non-ferrous metals with automatic feeding

Negative 2 -5° - Cutting of metals with manual feeding as well as plastic and laminate

Tooth Shape

- AA. Straight Teeth

- BA. ALTERNATIVELY BEVELLED TEETH

- DA. LEFT HAND BEVELLED TEETH

- CA. RIGHT HAND BEVELLED TEETH

- RA. TEETH HAVE A FLAT TOP & CONICAL SIDES

- EA/EAM. TRAPEZOIDAL TEETH

- EAXH. ALTERNATE FLAT SQUare / inverted V tooth

AA. Straight Teeth

- For Ripping and cross-cutting.

- Panel size sawing.

- For good surface finish.

BA. ALTERNATIVELY BEVELLED TEETH

- For Ripping and cross-cutting.

- Panel size sawing.

- For good surface finish.

DA. LEFT HAND BEVELLED TEETH

- For Ripping and cross-cutting.

- Panel size sawing.

- For good surface finish.

CA. RIGHT HAND BEVELLED TEETH

- For Ripping and cross-cutting.

- Panel size sawing.

- For good surface finish.

RA. TEETH HAVE A FLAT TOP & CONICAL SIDES

- For Ripping and cross-cutting.

- Panel size sawing.

- For good surface finish.

EA/EAM. TRAPEZOIDAL TEETH

- For Ripping and cross-cutting.

- Panel size sawing.

- For good surface finish.

EAXH. ALTERNATE FLAT SQUare / inverted V tooth

- For Ripping and cross-cutting.

- Panel size sawing.

- For good surface finish.

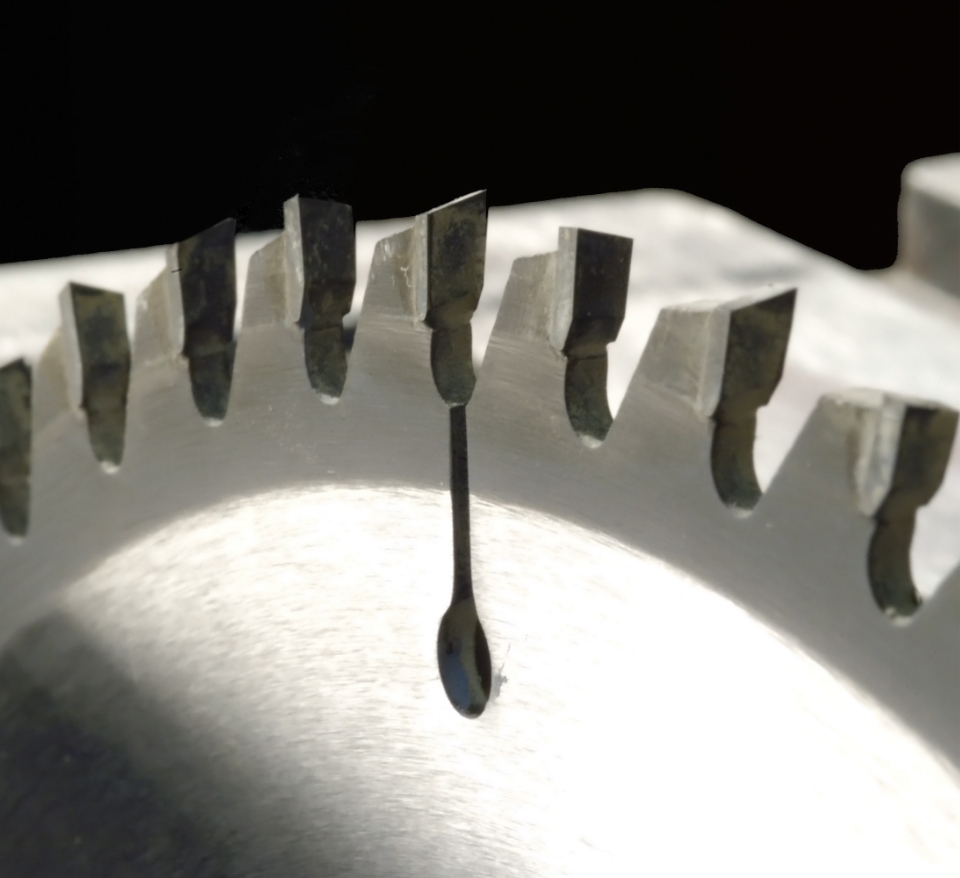

Tooth Pitch

Tooth pitch is an important factor when choosing blades for different types of work. The pitch is the distance between the front faces of adjacent teeth. The formula to the right can be used for calculating pitch

Designation “special”

| SPECIAL | DESCRIPTION |

|---|---|

| L | Laser dampened saw body. The saw blades are designed with thin laser-cuts. These reduce the noice and vibrations bye up to 40% |

| B2 | Large cutting width |

| T2 | Small cutting width |

| T3 | Extra small cutting width |

| T4 | Extremely small cutting width (with limited cutting depth) |

| S | Saw blades with guard teeth |

| R | Wiper slots saw blades |

| SR | Wiper slots saw blades with guard teeth |

| E | Dampened saw blade. Reduced gullets to reduce noise. |

Cutting Speed / Feed per Tooth

To optimise long life and good surface finish it is crucial to use the correct feed per tooth. If the wsaw blade has to low feed it results in quick wear. If the feed is to high it can cause teeth to break.

The recommendation table to the right, state cutting speed and feed rate per tooth for some different materials.

| MATERIAL | Cutting Speed [m/sec] | Feed rate per tooth [mm] |

|---|---|---|

| Solidwood - Cross cutting | 50-80 | 50-80 |

| Solidwood - Cross cutting | 60 - 100 | 60 - 100 |

| Solidwood - Cross cutting | 60 - 100 | 60 - 100 |

| Solidwood - Cross cutting | 60 - 80 | 60 - 80 |

| Solidwood - Cross cutting | 70 - 80 | 70 - 80 |

| Solidwood - Cross cutting | 70 - 80 | 70 - 80 |

| Solidwood - Cross cutting | 50 - 80 | 50 - 80 |

| Solidwood - Cross cutting | 50 - 80 | 50 - 80 |

| Solidwood - Cross cutting | 50 - 80 | 50 - 80 |

| Solidwood - Cross cutting | 50 - 80 | 50 - 80 |