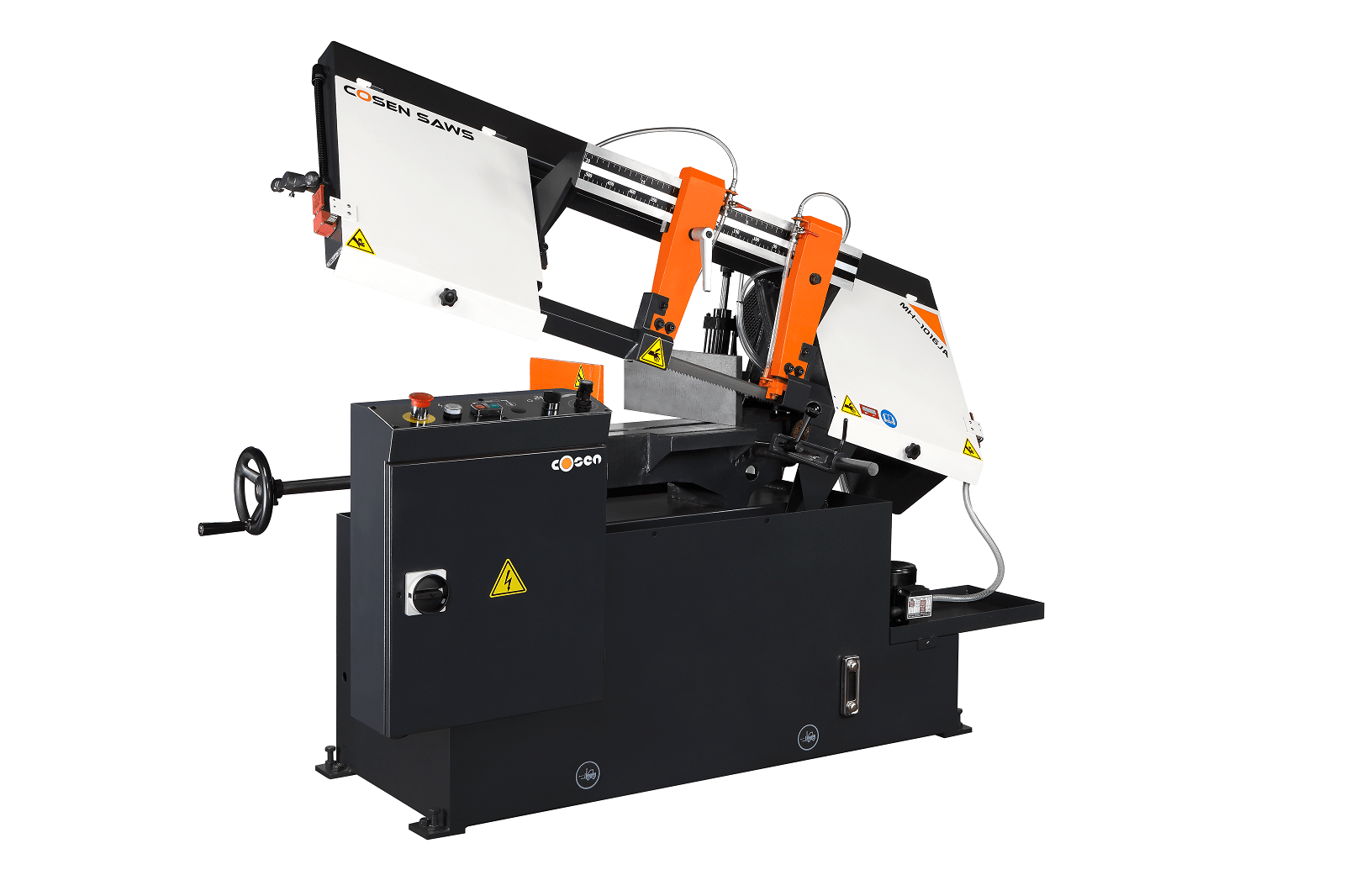

Manual

Our manual range of bandsaw machines are manufactured to the highest designs ensuring industrial duty, quality and reliability. We pride ourselves on offering best value to any job shop, tool room or secondary production unit to be handled precisely and efficiently. The machines are available as either standard pull down or with a gravity feed function. The gravity down feed function allows the bow to descend at a controlled rate. This dual action feature allows for using the pull down for fast sawing and operation of light jobs with the convenience of the hydraulic down feed for heavy tubes, profiles and solid stock. The mitre bandsaw range combines the advantage a circular cold saw with the speed of an abrasive saw and the capacity of a traditional bandsaw.

Benefits of using Sawcraft

We pride ourselves on working hand-in-hand with each customer to ensure that you take away the product that is right for you. We are a dedicated team with all the technical expertise required to formulate cutting solutions to meet individual sawing needs. Sawcraft is driven by quality but endeavours to find the most cost efficient cutting solutions. As specialists, we provide the complete range of saw blades and band saw machines at the forefront of research and technological development.