Cosen G300 Fully Automatic Bandsaw Machine

ENQUIRE ABOUT THIS MACHINEFeatures

Cosen’s G300 is a high production machine which incorporates a massive base, sturdy saw frame, with an extremely heavy duty gear box, a 3,75 kW drive motor, and a user friendly programmable control for ease of operation.

Cosen now offers the latest in Touch Screen Control Technology, SNC-100. Coupled with a Mitsubishi PLC controller the 5.7” Color Touch Screen allows for fast easy programming of any job. Utilizing the SNC-100 System the operator easily programs the cut length and quantity desired. The SNC-100 System stores up to 100 cutting jobs and features

Video

SPECIFICATIONS

| Capacity Round | 300mm |

| Capacity Square | 300mm |

| Capacity Rectangle(HxW) | 300x340mm |

| Bundle Cutting Width | 155 - 200 mm |

| Bundle Cutting Height | 50 - 120mm |

| Blade Speed | 20 - 100 m/min |

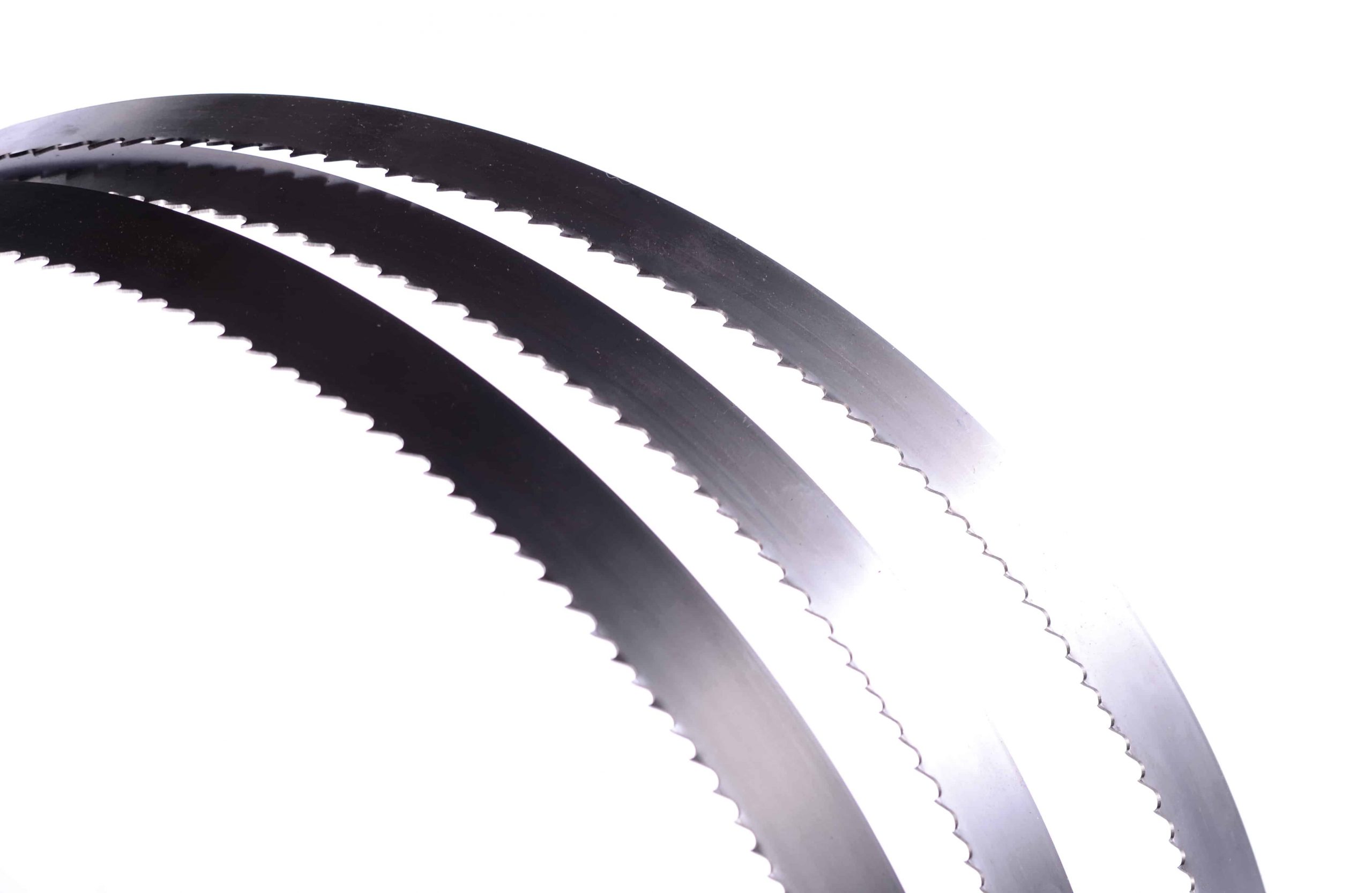

| Blade Size | 3820 x 34 x 1.1 mm |

| Blade Motor | 3.75kW |

| Hydraulic Motor | 0.7kW |

| Work Bed Height | 720 mm |

| Weight | 1800 kgs |

| Floor Space | 2010 x 1890 x 1530mm |

GET A QUOTE

"*" indicates required fields