G320 Automatic Bandsaw Machine

ENQUIRE ABOUT THIS MACHINEFeatures

The G320 fully automatic bandsaw machine is our No.1 top selling model due to the impressive output in relation to its size and cost. Specifically designed for mass production cutting on material up to 320mm diameter, bundle cutting options also available.

The dual column twin pillar design makes this machine a heavy duty and very reliable high performance industrial saw.

Video

SPECIFICATIONS

| Bundle Capacity | Width | 190x300mm |

| Height | 70x140mm | |

| Blade Speed | 20 - 100rpm | 66-328ft |

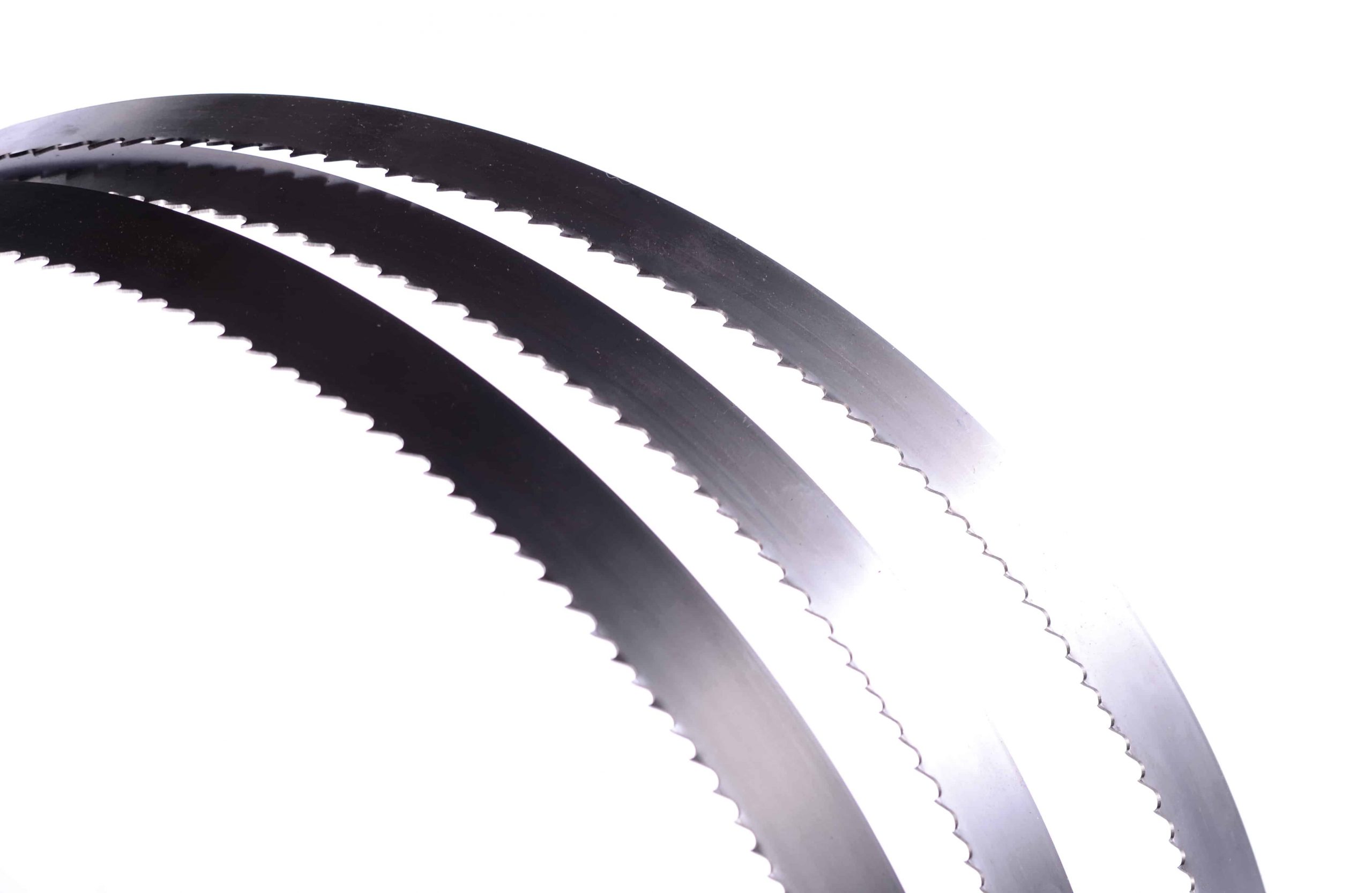

| Blade Size | 4240x34x1.1mm | 167"x1.3"x0.042" |

| Blade Motor | 5HP | 3.75kW |

| Hydraulic Motor | 1HP | 0.75kW |

| Coolant Motor | 1/8HP | 0.1kW |

| Work bed Height | 790mm | 31" |

| Gross Weight | 2200kgs | 4840lbs |

| Floor Space | 2010x2000x1900mm | 79"x79"x75" |

GET A QUOTE

"*" indicates required fields