Cosen C-460NC Automatic Bandsaw Machine

ENQUIRE ABOUT THIS MACHINEFeatures

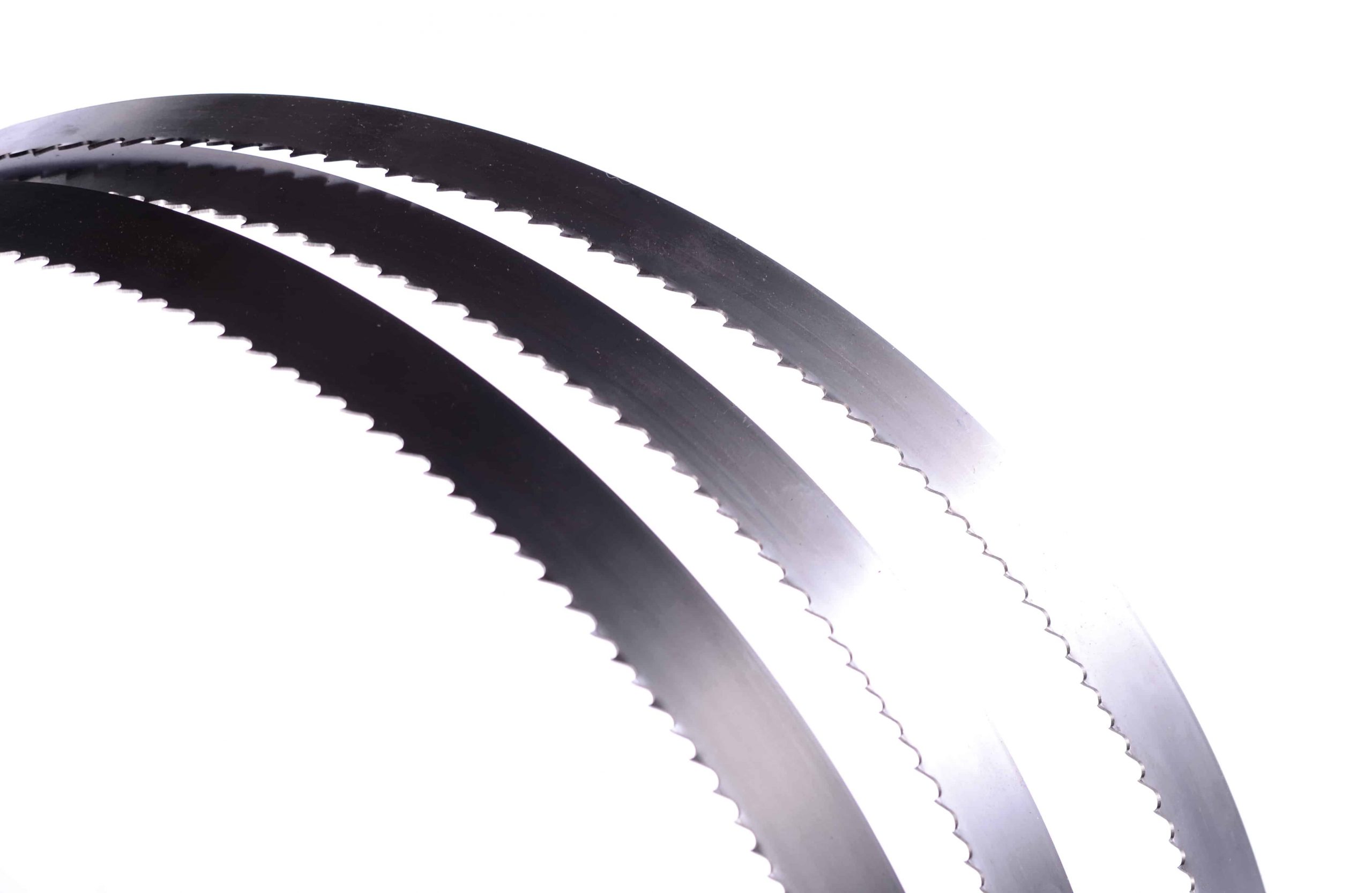

The C-460NC is a heavy duty, scissor action automatic bandsaw machine with a cutting capacity of 460mm. The saw incorporates a tilted saw bow design to reduce twist on the saw blade and maximise blade life.

SPECIFICATIONS

| Bundle Capacity | Width | 220 - 360 mm |

| Height | 95 - 230mm | |

| Blade Speed | 20 - 100 m/min | |

| Blade Size | 4670 x 41 x 1.3 mm | |

| Blade Motor | 5.5Kw | |

| Hydraulic Motor | 1.5kW | |

| Work bed Height | 750 mm | |

| Gross Weight | 2900kgs | |

| Floor Space | 2450 x 2310 x 2300 mm |

GET A QUOTE

"*" indicates required fields