C-520NC High Production Automatic Bandsaw

ENQUIRE ABOUT THIS MACHINEFeatures

The Cosen C-520NC high performance bandsaw machine incorporates the very latest Smart NC-100 technology. Programmable up to 100 different jobs including quantity and length of cut. Kerf loss is automatically compensated for after data input and requires no manual calculation.

The heavy duty compact design, makes the C-520NC one of the most cost effective versatile models on the market.

Video

SPECIFICATIONS

| Bundle Cutting Capacity | Width | 250 x 470mm |

| Height | 150 x 315mm | |

| Blade Speed | 20 - 100 m/min | 66 - 328 ft/min |

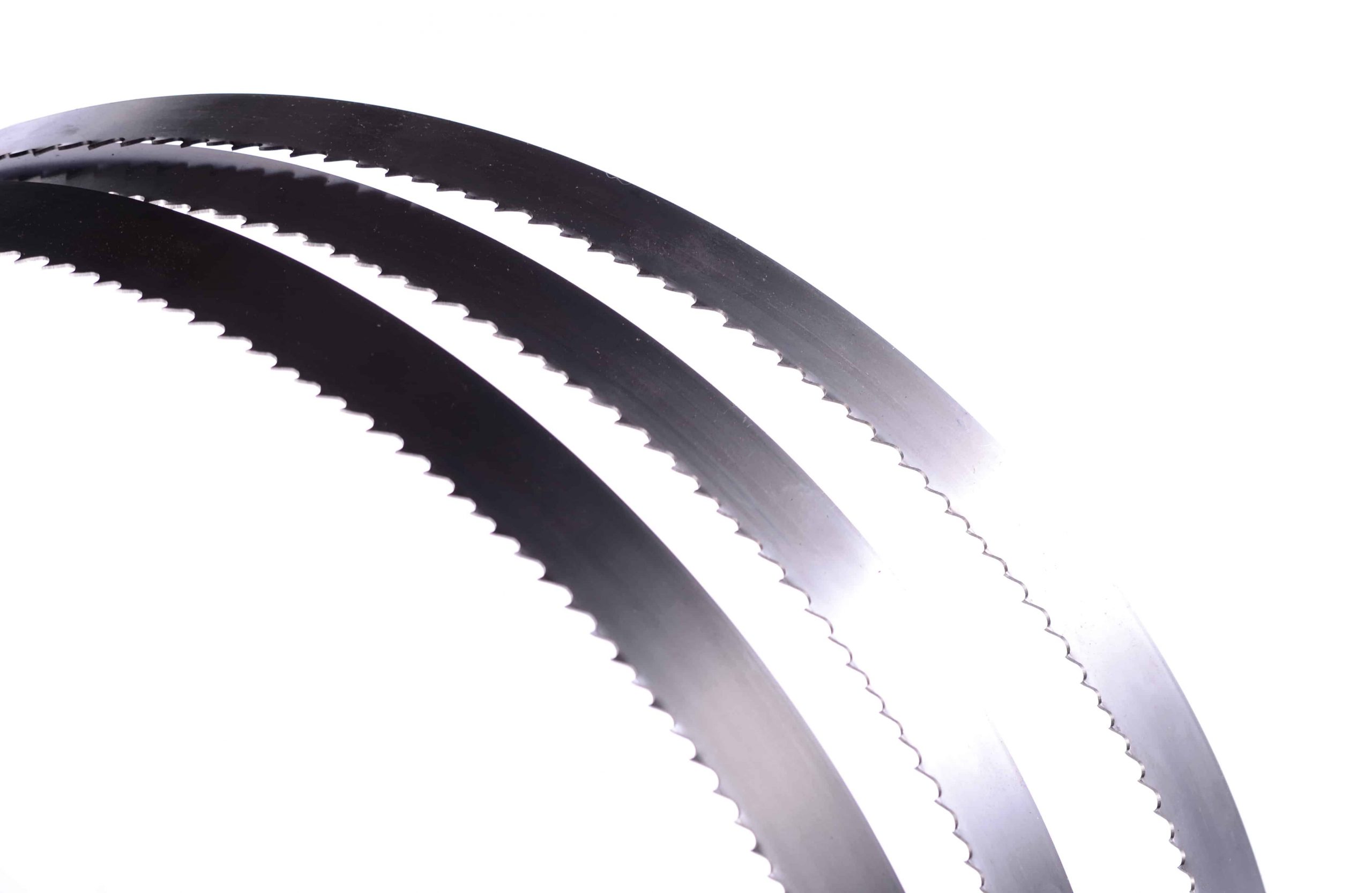

| Blade Size | 6040 x 54 x 1.6mm | 238" x 2.1" x 0.06" |

| Blade Motor | 7.5 HP | 5.6kW |

| Hydraulic Motor | 2HP | 1.5kW |

| Coolant Motor | 1/4HP | 0.1875kW |

| Workbed Height | 760mm | 30" |

| Gross Weight | 4300 kgs | 9460 lbs |

| Floor Space | 3175 x 2261 x2261mm | 125" x 89" x 89" |

GET A QUOTE

"*" indicates required fields