Cosen SVC-670DM Vertical Semi Automatic Dual Mitre Cutting Bandsaw

ENQUIRE ABOUT THIS MACHINEFeatures

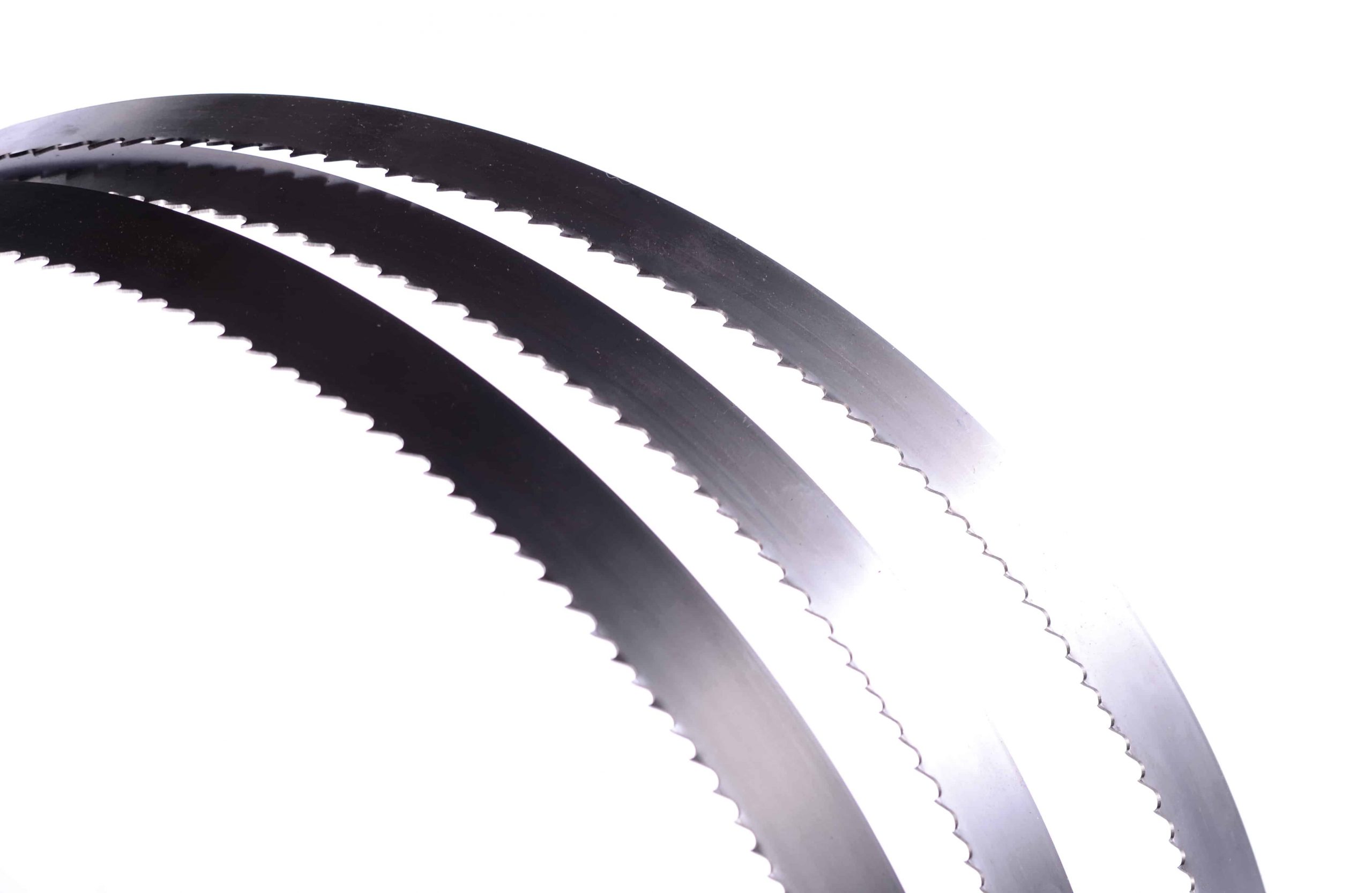

Cosens SVC-670 DM is a vertical semi-automatic dual mitre cutting bandsaw machine. Incorporates with a 3,75 Kw powerful blade motor and a 41 mm. wide blade, central control panel and a heavy duty design.

The saw frame tilts hydraulic or with by gear/chain motor to any degree between 60° left and right, making mitre-cutting extremely versatile and easy.

These features create a very rigid, dynamically stable and productive machine.

SPECIFICATIONS

| Blade Speed | 20 - 80 m/min Blade Size | |

| Blade Size | 4880 x 34 x 1.1 mm | |

| Tension | Hydraulic | |

| Saw Blade Motor | 3.75kW | |

| Work Bed Height | 1000mm | |

| Floor Space | 2500 x 2600 x 2500 mm |

GET A QUOTE

"*" indicates required fields