SH-1010W Heavy Duty Semi Automatic Bandsaw

ENQUIRE ABOUT THIS MACHINEFeatures

The SH-1010W is a large capacity semi automatic bandsaw machine for cutting material up to 1000mm diameter.

The heavy duty robust construction has a rigid dual column design with large diameter round columns are precision ground for precise control of the cutting process. A cross link between both columns is mounted at the top of each column to provide the maximum possible structural integrity.

SPECIFICATIONS

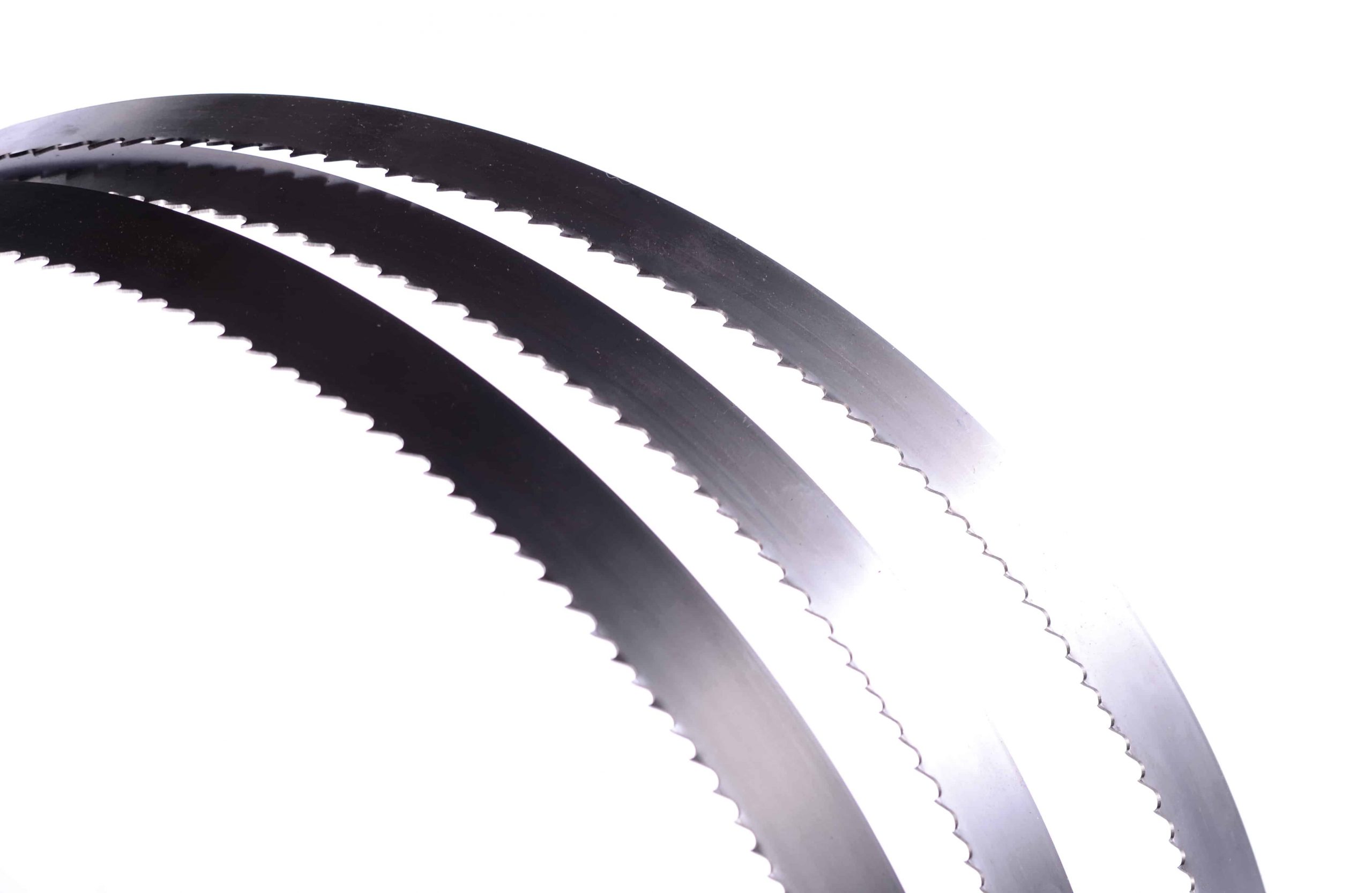

| Blade Speed | 15-80 m/min | 49 - 264 ft/min |

| Blade Size | 9400x67x1.6mm | 370"x2.6"x0.06" |

| Blade Motor | 15HP | 11.25kW |

| Hydraulic Motor | 3HP | 2.25kW |

| Coolant Motor | 1/2HP | 0.375kW |

| Work bed Height | 620mm | 24.4" |

| Gross Weight | 12000kgs | 26400kgs |

| Floor Space | 2300x5200x2700mm | 90.6"x204.7"x |

GET A QUOTE

"*" indicates required fields