SH-7662 Heavy Duty Semi Automatic Bandsaw

ENQUIRE ABOUT THIS MACHINEFeatures

The SH-7662 is heavy duty semi automatic bandsaw that offers precision cutting, efficiency in operation, low cost per cut and durability in a demanding production environment.

The twin column design offers a cutting capacity up to 620mm diameter on solid material.

SPECIFICATIONS

| Blade Speed | 20 - 100 m/min | |

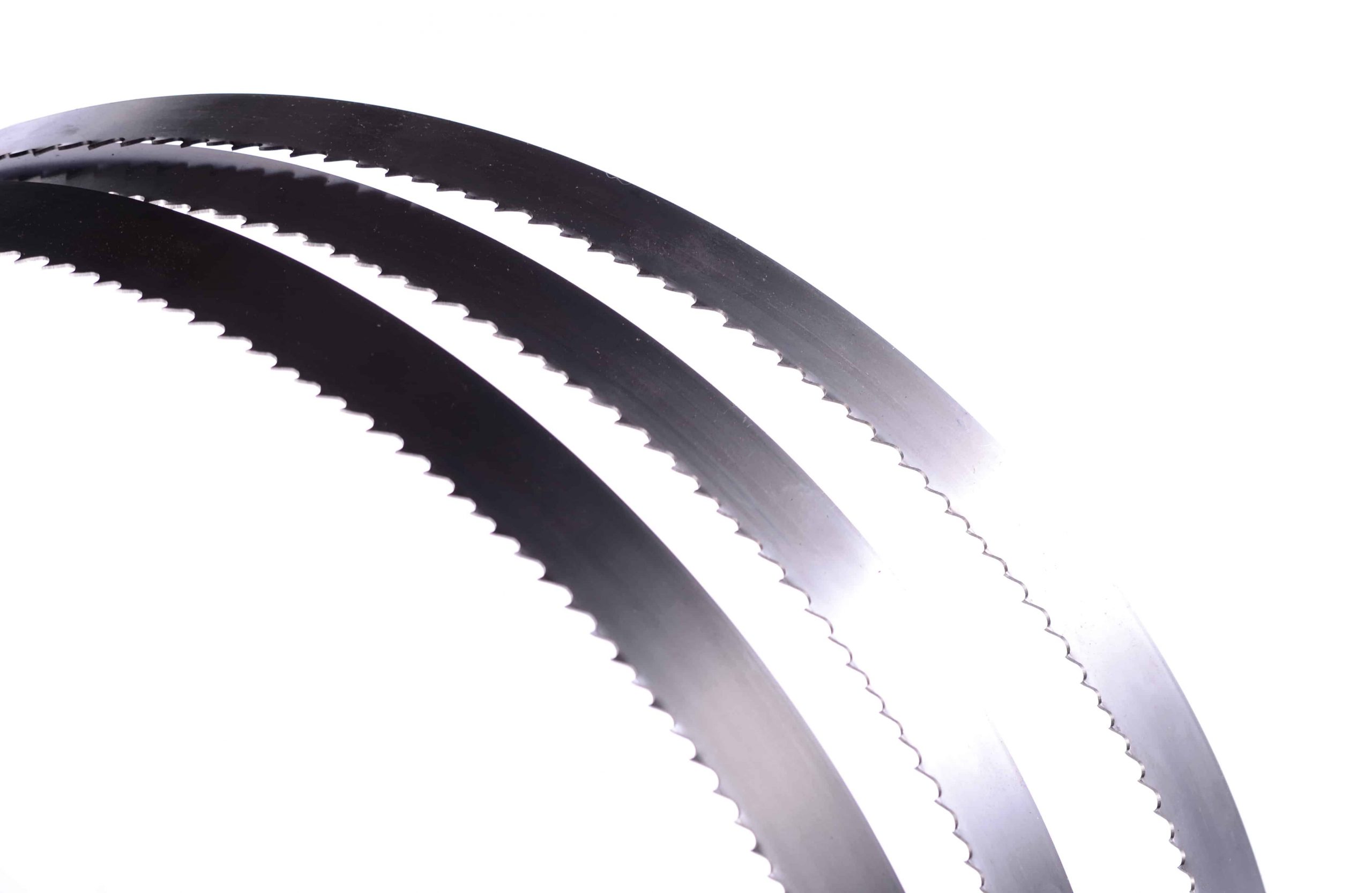

| Blade Size | 7200x54x1.6mm | 283"*2"*0.063" |

| Blade Motor | 10HP | 7.5kW |

| Hydraulic Motor | 2HP | 1.5kW |

| Coolant Motor | 1/4HP | 0.1875kW |

| Work bed Height | 600mm | 23.6" |

| Gross Weight | 3900kgs | 8580lbs |

| Floor Space | 1200x3560x2360mm | 47.2"x140"93" |

GET A QUOTE

"*" indicates required fields