C-650MNC Automatic Mitre Cutting Bandsaw

ENQUIRE ABOUT THIS MACHINEFeatures

The C-650MNC ia an automatic bandsaw machine for mitre cutting on material up to 420mm diameter. The swivel saw frame allows for precise and accurate angle cutting from 0-60º right.

Featuring in the Smart NC-100 technology, COSEN’s NC Automatic Miter-Cutting Band Saw is the way to boost your productivity in miter-cutting jobs.

This machine is ideal for structural material applications such as: I Beams, H Beam, pipe and channel.

Video

SPECIFICATIONS

| Mitre Cutting Capacity | Round +45 | 400mm |

| Round +60 | 250mm | |

| Rectangle +45 | 400 x 400mm | |

| Rectangle +60 | 400 x 250mm | |

| Blade Speed | 20 - 100 m/min | 66 - 330 fpm |

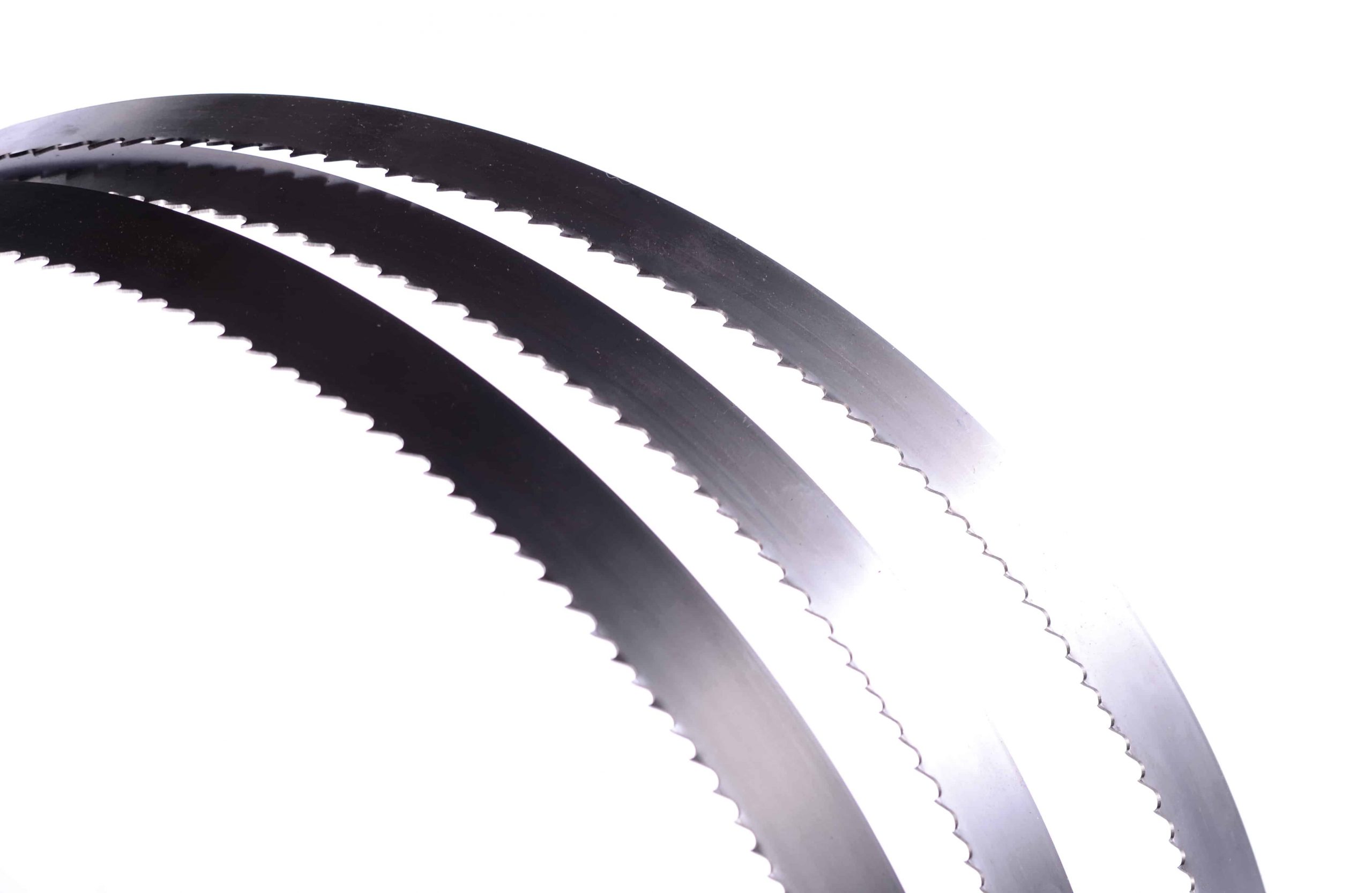

| Blade Size | 5300 x 41 x 1.3mm | 209" x 1.6" x 0.05" |

| Blade Motor | 7.5HP | 5.6kW |

| Hydraulic Motor | 2HP | 1.5kW |

| Coolant Motor | 1/4 HP | 0.18kW |

| Workbed Height | 750mm | 29.5" |

| Gross Weight | 3000kgs | 6600lbs |

| Floor Space | 3600 x 2900 x 2500mm | 141.7" x 114" x 98.4" |

GET A QUOTE

"*" indicates required fields